Beginning with the Doolittle Raids in 1942 to the Battles of Midway, Guadalcanal and Iwo Jima and ending with the final raids on the Japanese homeland in late 1945, one ship participated in and survived every major naval operation in the Pacific War. Although attacked and damaged from several bombings, the vessel never sustained a causality among its crew. This ship, however, was not a battleship, cruiser, or aircraft carrier but the USS Cimarron, an oil tanker built by the Sun Shipbuilding and Dry Dock Company of Delaware County in 1939. During the Pacific War, the USS Cimarron played a vital role in the Allied victory as it fueled more vessels than any other oil tanker in the fleet. This vessel is but a small example of the significant contributions the Sun Shipbuilding and Dry Dock Company made, not only to the shipbuilding industry, but to all of America and the world.

In 1916 brothers J. Howard Pew, president, and Joseph N. Pew, Jr., vice president, of the Sun Oil Company created the Sun Shipbuilding Company on the banks of the Delaware River in Chester, PA. Chester was an ideal site for a shipyard because “even in the 17th century, the people of the Delaware River Valley were bent on outstripping the world with the size and speed of ships,” Joseph N. Pew, Jr., explained to the Chester Times. Sun Ship was founded because the Sun Oil Company needed tankers to transport crude oil from its fields in Texas to its oil refinery in nearby Marcus Hook, PA. The First World War was raging on, and the Pew brothers understood the damage Germany inflicted on American shipping, specifically oil tankers. Thus, at a cost of $5 million, the Pew brothers transformed 50 acres of skunk cabbage into a major commercial shipyard.

On October 30, 1917, during a rain and sleet storm, Sun Ship launched its first vessel, the 10,600 dead-weight-ton freighter the SS Chester Sun. After the launch, J. Howard Pew described the event to The Philadelphia Inquirer:

In spite of the terrific downpour everything went as smoothly as clockwork. We wouldn’t postpone the launching for the superstition of the sea has it that if a launching is postponed the ship will be a “hoodoo” vessel. If everything goes as smoothly for the Chester Sun as the launching went she should be anything but a “hoodoo.”

It certainly was not “hoodoo” for the Sun Shipbuilding Company because, over the next six decades, almost 700 ships followed in the SS Chester Sun’s footsteps, gliding into the waters of the Delaware River.

Sun Ship contributed greatly to World War I by undertaking many shipbuilding and repair contracts. Over 10,000 people were employed at the shipyard during the peak war period. By war’s end, the shipyard had produced three minesweepers and six oil tankers for the US Navy. After the war, Sun Ship built its first dry dock and created a ship repair department. The company’s name was changed to the Sun Shipbuilding and Dry Dock Company to incorporate its new operation.

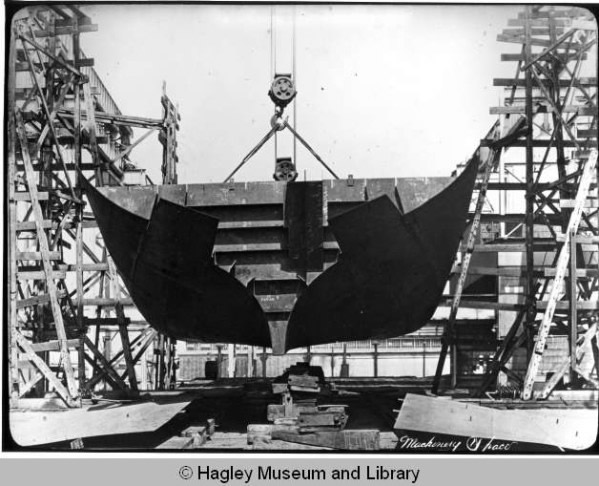

When the Pew brothers purchased the land for the shipyard, they also acquired the Robert Wetherill Engine Works machine shop and foundry. The plant was transformed into the machinery unit of the shipbuilding company. It was in this location that the famous Sun-Doxford Diesel Engines were built. Prior to 1923 boilers and steam engines were used as the main propulsion for tankers and cargo ships. These engines were soon fading out of use, and Sun Ship, with a focus on the future, became the sole licensee for the Doxford Diesel Engine developed by William Doxford and Sons Engine Works in Sunderland, England. At the time, Sun Ship became America’s largest builder of marine diesel engines, and the Sun-Doxford diesel engine provided the main propulsion for more vessels than any other type of diesel engine. This was a major contribution to the shipbuilding industry, but was not the only development made at this time.

Prior to 1922 riveting was used to build pressure vessels and ships and welding was used only for repairs. Sun Ship pioneered the technology and use of welding to replace the riveted plates when building pressure vessels. The company did a great amount of research and development on welding technology and was able to apply it to shipbuilding. On September 10, 1931, the shipyard launched the first all-welded ocean-going vessel, the SS White Flash. This launch marked a new era in shipbuilding. The riveted method was labor intensive, costly, and allowed for seawater to enter the vessel. Replacing rivets with welds decreased build time and costs and increased the strength of the ship. This development allowed the U.S. shipbuilding industry to produce three times as much tonnage during World War II than could have been produced using the riveted method.

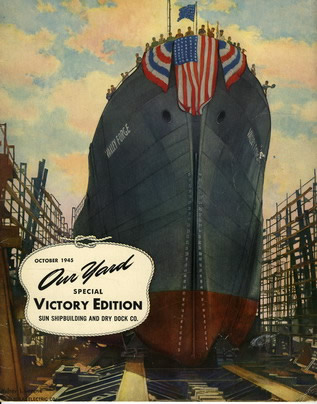

With America on the brink of World War II, the merchant tanker fleet was not adequate to support a war in Europe and the Pacific. German U-boats terrorized the Atlantic, destroying a large portion of American shipping. By 1943, the American navy took control of the Atlantic, and shipyards, such as Sun Shipbuilding and Dry Dock Company, hurriedly made up for the lost ships. Sun Ship needed to expand its shipyard in order to meet the demand of ships for the United States Maritime Commission. The yard increased from 8 to 28 shipways during the war, covering a mile and a half of riverfront.

The United States Maritime Commission, created by the federal government to oversee a merchant shipbuilding program, was in desperate need of oil tankers. Sun Ship, on the forefront of tanker production and technology, redesigned its oil tanker and created the T-2 tanker. This became the standard oil tanker during the war and could hold over 141,000 barrels of oil. During the war, Sun Ship produced 285 vessels, mostly oil tankers, and accounted for 40 percent of the oil tanker fleet in the United States. Understanding the importance of this, historian John Bunker noted in his book Heroes in Dungarees: The Story of the American Merchant Marine in World War II that “the United States furnished 80 percent of the oil and gasoline during World War II and the tanker fleet of this country delivered this life blood of battle.”

The shipyard averaged construction of one ship a week during peak production. The focus for the shipyard, however, was not only on ship production but also on ship repair. From Pearl Harbor to the end of the war, Sun Ship repaired over 1,500 vessels that had been damaged by bombs, torpedoes, mines, or other weapons of war. Because of the number of ships that passed through Sun’s shipyard during the war, the contributions Sun Ship made to the war effort were monumental. Paul Burke, a member of the Navy’s Armed Guard who worked at the shipyard for a brief time during 1943, explained to the Delaware County Sunday Times that “to put out that many ships in such a short amount of time was miraculous – without them we couldn’t have won the war.”

World War II marked the peak of Sun Shipbuilding and Dry Dock Company’s production. Over five years, from 1938 to 1943, the workforce grew from about 3,000 employees to the highest employment at the shipyard of 35,633 employees. This enormous growth made Sun Ship the largest single shipyard in the entire world. Of this large workforce, 2681 were women, and they were respectfully referred to as “Tillie the Toiler” as opposed to “Rosie the Riveter.” There were also about 12,000 African American workers employed at the shipyard. Richard L. Burke, vice president at the time, reported in a company publication that Sun Ship set a “notable precedent” with “every department thrown open to Negro workers on equal terms.” Most of the African American workers were employed at the No. 4 yard, where the first ship built entirely by African Americans, the SS Marine Eagle, was launched.

Paul Burke, in an interview with the Delaware County Sunday Times, examined the wartime workforce at the shipyard saying “while I was at Sun Ship, they had three shifts going…all [the workers] needed was a place to sleep because they were working seven days a week and all the overtime they could handle.” Not only did the Sun Ship workers sacrifice their time and energy for the war, they also bought $36 million worth of war bonds through deductions from their wages. The success of Sun Ship, and ultimately the war, stemmed from this loyal and dedicated workforce. On March 23, 1943, Sun Ship and its employees received the U.S. Maritime “M” award for their contributions to the armed forces.

In the years after the war, Sun Ship continued to develop advancements in shipbuilding. The shipyard produced the world’s largest hopper dredge for the Army Corps of Engineers as well as launched the first supertanker, a vessel capable of holding 10,000,000 gallons of oil. However, the need for new ships was on the decline and Sun Ship switched its focus to modernization, ship technology and repair, and non-marine work.

Sun Shipbuilding Company developed the Aero/Hydrospace and Industrial Products department. Sun Ship used this department, along with its efforts in metallurgy, welding, and precision machinery and tooling, to work on and explore non-marine projects. This department produced the support anchor components for the Verrazano Narrows Bridge, which connects Staten Island and Brooklyn, NY. In cooperation with NASA, the Aerospace division developed the solid propellant rocket motor cases for the Atlas rocket, which brought the first Americans into orbit, as well as hold-down clamps for the 7.5 million pounds of thrust of the Saturn V rocket, which placed the first men on the moon. Sun Ship also made advancements in marine technology at this time. On October 17, 1967, the Adm. William M. Callaghan was launched. At the time it was the fastest and largest cargo ship ever built, and it was the first to be powered by jet engines. It set a world record by crossing the Atlantic Ocean in only four days. The shipyard also converted the oil tanker, USS Manhattan, into an ice-breaking tanker. The vessel was the first in history to successfully navigate the Northwest Passage, and it paved the way for the transfer of crude oil from Alaska to the East Coast of the United States.

Along with its marine and non-marine advancements, Sun Ship was involved in a number of special projects contracted through the U.S. government. In the early 1970s, the Aero/Hydrospace division created a prototype of the Deep Submergence Rescue Vehicle (DSRV). The vehicle allowed the U.S. Navy to work at depths of over 3,500 feet for 12 hours to rescue the crew of a damaged or sunken submarine. It is compact enough to be transported to an emergency site in 4 hours, and the three man crew is capable of rescuing 24 survivors at a time. The ship construction that brought the most press and scrutiny was the development of the Hughes Glomar Explorer. The vessel was financed by the CIA but was constructed in secret. It was reported that the ship was to be used in billionaire Howard Hughes’ underwater mining operation. However, this was simply a front. The secret operation entitled “Project Jennifer” was actually a CIA mission, constructed through Hughes, to recover a Soviet submarine that sank in 1968. Discovered in the height of the Cold War, the submarine supplied evidence of the Soviet use of sea craft with nuclear missiles and torpedoes.

Sun Ship faced a number of factors in the late 1970s that lead to its eventual demise. These factors included increased foreign competition, rising steel and fuel prices, decreased government contracts, and a worldwide economic recession that greatly hindered the shipbuilding industry. The last ship built by Sun Shipbuilding and Dry Dock Company, the SS Kauai, launched on October 31, 1979, 63 years and one day after the company launched its first ship. In 1982, the Sun Oil Company, now Sunoco, sold the Sun Shipbuilding and Dry Dock Company to a Texas businessman, Ed Paden, and the yard was renamed Pennsylvania Shipbuilding.

Pennsylvania Shipbuilding experienced its own hardships and closed in 1989. The site remained abandoned for many years until it was selected as the site for a racetrack. All of the buildings and structures have been demolished; the last structure came down in 2005, and the site is now Harrah’s Chester Casino and Racetrack. All that remains of the Sun Shipbuilding legacy, in the original location, is a historical marker on the side of PA Route 291 at the entrance to the casino property. Although the buildings have been demolished, the impact of the Sun Shipbuilding and Dry Dock Company lives on.

Dave Kavanagh, a former Sun Ship employee, created the Sun Ship Historical Society to commemorate the importance of the company. The Sun Shipbuilding Company had a major impact on the Delaware Valley. Through its 66 years of existence, the shipyard employed almost 100,000 men and women. Kavanagh told the Delaware County Daily Times in an interview that “Sun Ship supported generations of families in the Delaware Valley; you almost couldn’t meet anyone who hadn’t worked there, or didn’t know someone who had.”

The legacy of Sun Ship lives on in the memory of employees and their families because they were strongly connected to the institution. Kavanagh explained, “you could work your way from the bottom and if you had the wherewithal and work ethic, you could advance yourself very rapidly. Sun cared for its employees. It was like a large family.” The Sun Shipbuilding and Dry Dock Company provided for its workers and their families, and kept an entire town afloat throughout the years. The impact of this company, however, can be seen throughout the entire world. Many revolutionary vessels and important advancements in shipbuilding were developed at the shipyard. The importance of Sun Ship will never be forgotten as its 66 years of production fueled wars, victories, a town, and its people.

Sources:

- “35-Year-Old Sun Shipyard Reached Peak in World War II with 350 Vessels Built.” Chester Times 7 Sept. 1951: 13.

- Bunker, John. Heroes in Dungarees: The Story of the American Merchant Marine in World War II. Annapolis, MD: Naval Institute Press, 1995.

- Costello, John, and Dave Kavanagh. “Sun Shipbuilding and Dry Dock Co. - 1916 - 1918: A Short History.” Sun Ship Historical Society Website. The Sun Ship Historical Society, 2007. Web. 15 Sept. 2010.

- Fowler, Judy. “Sun Ship Launches Revolutionary Vessel.” Delaware County Daily Times 18 Oct. 1967: 1.

- Fowler, Judy. “Jet Ship Marks 50 Years of Construction for Sun.” Delaware County Daily Times 28 Oct. 1967: 11.

- “History of Sun Shipbuilding and Dry Dock Company.” Our Yard Sept. 1941: 4-5.

- Kennedy, Joseph S. “Sun Ship helped fuel victory in WWII.” Philadelphia Inquirer 18 Aug. 2002.

- “Launch New Ship In Heavy Downpour.” The Philadelphia Inquirer 31 Oct. 1916: 10.

- O’Neill, Robert F. “Sun Ship Raises Sights Into Space, Joins Project to Send Man to Moon.” Philadelphia Evening Bulletin.

- Puglionesi, Lois. “Sun Shipbuilding and Drydock Eclipsed By Time.” Delaware County Daily Times 26 Sept. 2004.

- Roman, John M. “Mystery Ship.” Delaware County Daily Times 20 Dec. 1999: 7.

- Roman, John M. “The WWII Effort.” Delaware County Sunday Times 19 Dec. 1999: 4.

- Smith, Eric. “Trouble in River City.” Delaware County Daily Times 6 Oct. 1989: 18.

- “Sun Shipbuilding and Dry Dock Company” company publication photocopied from the Delaware County Historical Society