Snuggling up in front of the fireplace under a warm wool blanket, trekking through the woods while hunting in a fleece jacket, or hiking up a snowy mountain in durable boots: These activities would not be as enjoyable as they are for many were it not for John Rich II and his establishment of his woolen mill. The Woolrich Woolen mill, located in Woolrich, Clinton County, is the U.S.’s oldest continuously operating woolen mill. The company calls itself “The Original Outdoor Clothing Company.” For over 180 years, Woolrich has supplied quality clothing items to hikers, hunters, and other outdoor enthusiasts.

John Rich II emigrated to the U.S. from the midst of English wool-country. Although Rich lived in the middle of a rich region, he himself was not wealthy. Rich hoped for a more rewarding life when he left England aboard a ship headed for the United States. Upon his arrival, he stayed true to his family’s heritage, renting a small mill in Mill Hall, Clinton County, and saving his money to build his own factory.

The first Woolrich-owned woolen mill was established in Plum Run, Clinton County, in 1830 by Rich and his partner, Daniel McCormick. While north-central Pennsylvania might seem an odd location to found a woolen mill, it turned out to be an ideal location for Rich. Northern and central Pennsylvania was experiencing a lumber boom that would make nearby Williamsport, Lycoming County, at the time home to more millionaires per capita than any other place in the world. Plum Run proved to be a perfect location for a mill because Rich could travel to the lumber camps with woolen fabric in a mule cart to sell to the wives of lumberjacks. The wives then made finished clothing products for their husbands. He also sold socks, coverlets, and yarn. After only a few years, the location turned out to be a disappointment because little Plum Run just could not supply the waterpower needed.

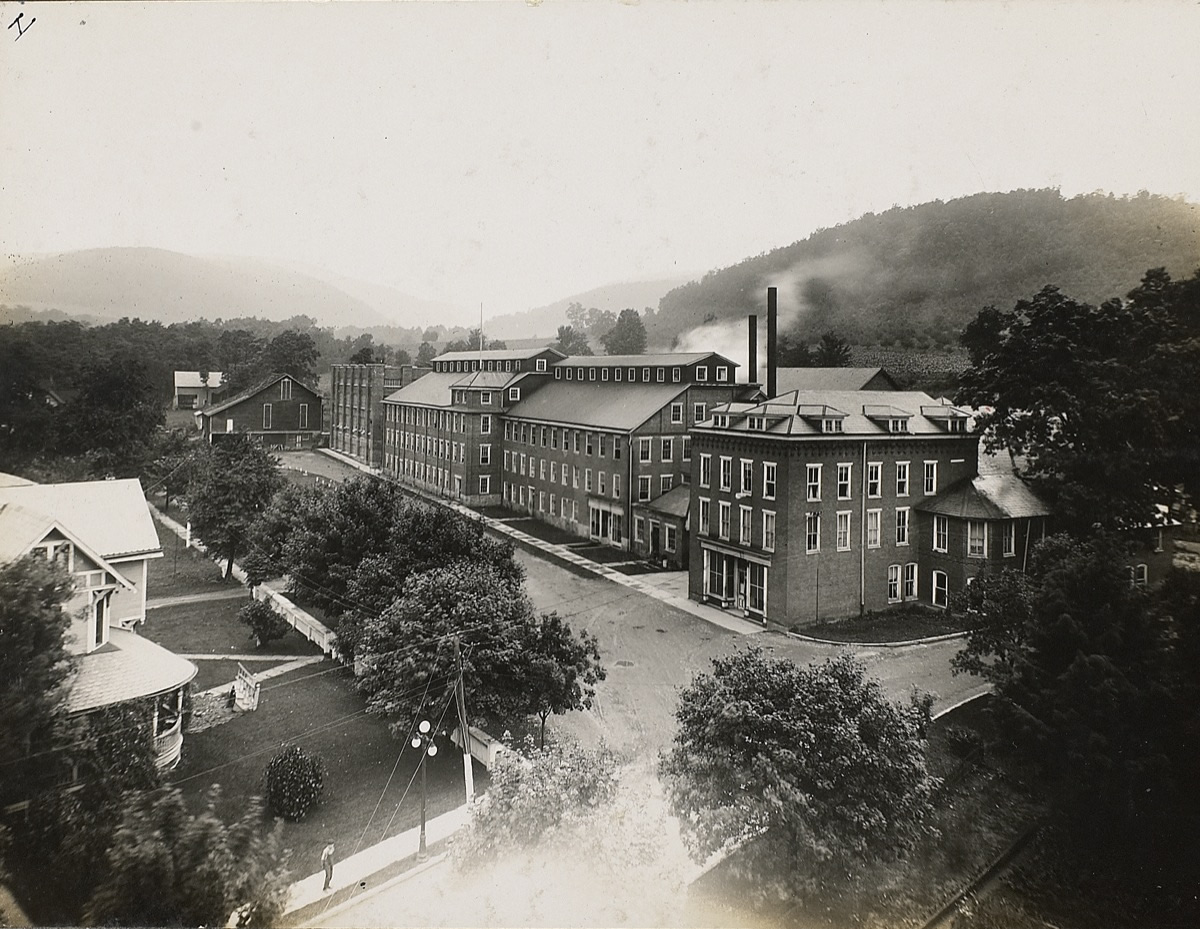

In 1834, Rich and McCormick purchased 300 acres in Pine Creek Township, Clinton County, along Chatham Run, a few miles north of Plum Run. Rich built a sawmill to provide lumber for three log houses and the new expanded woolen factory. Nine years passed before the factory was completed. During 1843, Rich bought McCormick’s share of the company and opened the new mill as its sole proprietor two years later. The mill required a substantial number of employees to operate and as employees and the Rich family built homes around the mill, a close-knit community developed. This area was originally known as Factoryville, then Richville, and finally in 1888 was named Woolrich, and today remains the home to the original woolen mill and the company’s headquarters.

As the business and community continued to grow, and with technological advancements, Woolrich began to develop better quality products to keep up with the lifestyle changes of each new generation. With the help of new production methods and industrial advancement, the company made finished products including wool shirts, jackets, breeches, and caps, along with its woolen fabrics. The new technology and materials, such as the sewing machine patented by Elias Howe in 1846, allowed Woolrich to improve the performance of its outerwear. In fact, Woolrich was the first company to use a zipper in men’s trousers.

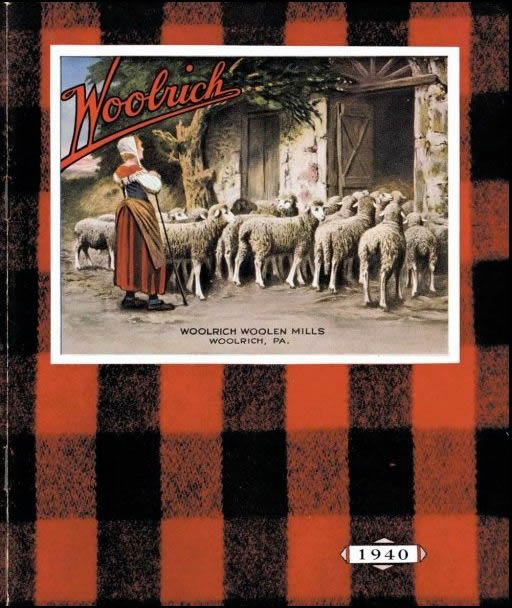

One of the earliest finished clothing items produced at the mill was the Buffalo Check Shirt in 1850. The name was inspired by a herd of buffalo owned by the designer at the company who developed the pattern. The Buffalo Check pattern became popular with the lumberjacks, railroad workers, and others who had to work outdoors for a living. So successful is this pattern for the company that it uses it as a part of its corporate logo. Later, as time spent outside became a choice rather than a work-based necessity, Woolrich adapted. A pattern similar to the Buffalo Check was used in clothing geared to the hunting market in central Pennsylvania. In catalogs, the red- and black-patterned jacket and pants was called the “Woolrich Big Game Hunter’s Suit.” In the Keystone State, it became known as “the Pennsylvania Tuxedo.”

Another hit item was the Railroad Vest, which was used by railroad workers, lumbermen, hunters, and trappers because, not only did it keep them warm, it also had four storage pockets for gear. The Railroad Vest was first introduced when the railroad was being built throughout Pennsylvania. It was produced specially for railroad men because they needed pockets for their watches; hunters and trappers also adapted the vest because of the versatility the pockets offered.

Other popular items produced by Woolrich included the Chamois Shirt and the Arctic Parka. The Chamois Shirt is made of thick 9-ounce material for demanding outdoor work and adventure. The Arctic Parka is unique because it can keep the body warm in temperature up to 40 below zero. While all of these items have been modified slightly throughout the years and now include models for women, they continue to be popular to this day.

Woolrich does not just provide warm clothing for cold outdoor activities. In the late 1920s, the company began producing leisure wear. Some of these products included woolen bathing suits and golf pants. The addition of these leisure products made Woolrich a more well-rounded company by providing items for all seasons and providing apparel for more customers.

The mill would not be as proficient and successful as it is, were it not for the great leaders of the company throughout the years. Many members of the Rich family, both men and women, have played an important part in the growth of Woolrich. In 1857, an agreement was made to divide the company equally between Rich and his son J.F. Rich, and the company became John Rich & Son. This was the first of several name changes that occurred as new partnerships were formed. In 1930, the company was incorporated as the Woolrich Woolen Mill, bringing the name of the company into harmony with that of the town.

J.F.’s son, M.B. Rich, was behind many improvements of the business, including adding new equipment, expanding the factory, and improving the reputation of the company. M.B. also partnered with his father and his brother, John Rich, and the company was renamed J.F. Rich & Sons. Most notably, M.B. helped to establish Woolrich in the growing business world. In Woolrich: 175 Years of Excellence, Doug Truax refers to an article in the Clinton Republican that stated “…[the firm] has been steadily building up under the leadership and business-like manner, and the high esteem in which he is held by the citizens of his community is a high tribute to any man.” The Norway Spruce trees that line the mile-long road into Woolrich were planted in 1930 in memory of M.B. Rich.

One of the biggest contributions to the nation that Woolrich has made is supplying servicemen and women with socks, blankets, and coats during the Civil War, and the first and second World Wars. The blankets provided warmth and comfort to the soldiers. The large number of warm and durable items required by the troops put heavy demands on the mill. Workers needed to pick up extra shifts, new facilities were needed, and quality control was essential in producing the products on time. Even today, Woolrich supplies servicemen and women with quality clothing and accessories. They are, for example, the makers of the official US Army blankets, the official US Navy peacoat fabric, and are the sole supplier for the U.S. Marine scarlet, seen primarily in their dress uniform pants.

Woolrich is the only U.S. woolen mill still in production that supplied woolen items to the Union troops during the Civil War. Re-enactors and film studios seek out Woolrich to acquire accurate representations of the blankets and uniforms. Woolrich today offers Civil War commemorative blankets that are crafted in the mill as they were in the 1860s.

In 1939, Woolrich provided gear for Admiral Byrd’s third expedition to Antarctica. According to Truax, the clothing items needed to sustain temperatures that would reach 60 degrees below zero and included medium and heavy wool shirts, reinforced ski pants, special red-and-black hunting breeches, 32-ounce wool pants, and special virgin wool hunting coats. Woolrich supplied quality products to the crew who successfully explored and surveyed areas on Antarctica for an extended period of time.

Nearly 70 years later in 2010, Woolrich supported another expedition to Antarctica led by Dale Andersen. His expedition lasted three months during which he explored isolated waters for microbial life in such an extreme setting. Andersen said, “Maintaining personal comfort and warmth is always a challenge in the Antarctic and Woolrich has always been one of the best when it comes to making a shirt that can stand up to the elements.” Ever since Andersen was in Boy Scouts, he has been using wool materials provided by Woolrich to keep him warm in cold environments. Woolrich is provided Andersen with mid-layers, socks, headwear, and outerwear to use and provide feedback during this and future trips. Along with the iconic Buffalo Check Wool shirt, Andersen will be testing the new Woolrich Lahar Vest and Zip-Neck merino wool mid-layers. The feedback that Andersen will provide will help Woolrich make adaptations to the products so they can better meet the needs of their future customers in extremely cold environments.

In 1989, the company had ten plants located in the United States and one near Montreal and had made more improvements to their outerwear. Woolrich had begun marketing synthetic fabrics such as Endurich Cloth. The cloth is a fast-drying safety orange fabric. The company also incorporated a machine washable wool fabric in its Malone Hunting Pants. It was already selling integrated outerwear systems featuring weatherproof shells with zip-in, insulated jackets.

COMMUNITY INVOLVEMENT

To a certain extent, all companies are involved with their communities; most, however, limit that involvement to hiring workers and disbursing paychecks. The relationship between the Rich Family, the Woolrich Company, and the town that sprang up around the mill has been much more intimate than merely a typical “boss and workers” relationship.

The Woolrich Family, as Finishing Manager Ron Yeaton referred to it, put together the Woolrich Employee Benefit Association to work on behalf of the workers and the rest of the community of the home plant. They have, for example, maintained the town’s park since the 1940s, refurbishing it periodically and updating equipment when needed. The park has been the site of their annual employee picnic for years as well. On a more serious note, the Association provides financial assistance where possible to needy employees through its Hardship Committee and gave out over 20 scholarships to college in 2010.

The people of Woolrich, Inc. have also reached out to the world beyond Clinton County. A few years ago, one of the employees of the company had been to Washington, DC and had found himself so moved by the sacrifices made by returning, injured veterans that he returned to Woolrich, hoping the company could do something to help. After some discussions and some brainstorming in the design department, the company began producing the “Freedom Throw.” Since its inception, the Freedom Throws have been delivered to the Walter Reed Army Hospital and distributed to injured veterans as a token of the company’s and the workers’ appreciation.

The Rich family itself has also felt a call to service beyond the corporate offices. Michael Bond Rich, in addition to writing a history of the first hundred years of the town of Woolrich in 1930, served two terms in the Pennsylvania General Assembly and did much work for the local Methodist Church. His son, Robert Fleming Rich, was a member of the United States House of Representatives from 1931 to 1951, with a break in 1944 when he declined to run for re-election.

Woolrich continues to do more than supply clothing to outdoorsmen and women. In Woolrich Marking 175th Year as an Outdoors Icon, former CEO President Roswell Brayton, Jr., said, “To me, personally, one of the most important things we do is keep open almost 5,000 acres here on the mountain so that the public can hunt, fish, hike or just enjoy the outdoors right here.” Clearly, Woolrich’s commitment to the great outdoors extends beyond the clothing it produces.

SURVIVING IN A ROUGH WORLD

Making a go of it in the textile business has never been an easy task. In addition to the economic situations, which have generally sent textile production overseas, manufacturers who weave their cloth from natural materials are at the mercy of Mother Nature. Cotton crops can be ruined by the boll weevil and numerous other pests and fungi. Silk worms can be killed by fungi and microsporidia of various sorts. Linen makers must depend on flax crops surviving attacks from various insects as well as the weather.

Woolen mills too have their difficulties. It is important to remember that, fundamentally, wool is hair—sheep hair. As such its qualities can vary wildly from sheep to sheep, herd to herd, and breed to breed. There used to be great numbers of woolen mills in Pennsylvania. M.B. Rich notes in his History of the First 100 Years in Woolrich the great decline in woolen mills even by 1930. He writes that in 1875 there were 21 or more woolen mills within a 75-mile radius of Woolrich; by 1930, there were only four or five.

Ron Yeaton notes that the sheep producers of the Northeast did not help the cause of Northeastern woolen mills. In their desire to increase the numbers of sheep on their farms, he says, farmers would cross-breed several varieties of sheep. Though this had a salutary effect on their ability to increase their herds, its effect on their coats was detrimental. With increased cross-breeding came an increase in the amount of black hair in the fleeces sheep grew. While the black hair is certainly useful—just look at the Buffalo Check fabric—it also reduces options for the woolen makers. Black wool will not absorb dye as white wool will. Moreover, it is very difficult to extract the black hairs from the white ones. The sheer cost of extraction proved too much and mills like Woolrich had to look elsewhere for their fleeces.

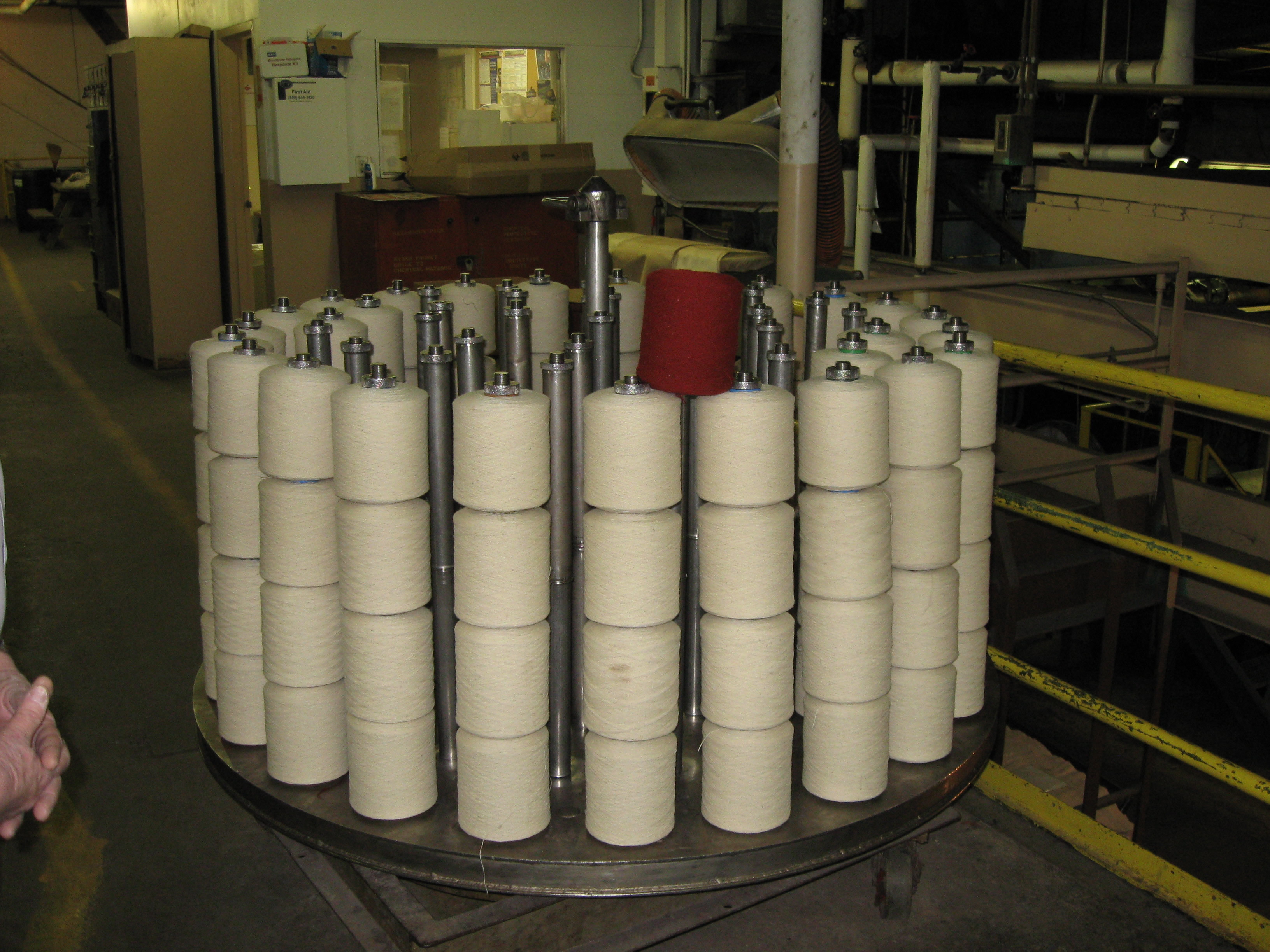

Though Woolrich has been forced by economic pressures to relocate much of its production overseas, it proudly maintains the home plant in Clinton County. In fact, according to company president James E. Griggs, Woolrich is one of only two “vertically-integrated” woolen makers in the United States. What does that mean? Woolrich is one of only two manufacturers who perform the entire process of woolen making, from receiving the raw wool to blending the types of wool together, from carding the wool and spinning the yarn to weaving and felting the cloth, and from dyeing to dry-finishing the fabric.

What allows the company to thrive in an environment that has driven virtually every other producer entirely overseas or to outsource various stages of production? According to Yeaton, it’s Woolrich’s size and flexibility. Because Woolrich is a smaller manufacturer and because it has taken the attitude of no job being too small, the company is able to accept smaller runs of fabric than larger firms are willing to produce. This allows Woolrich to occupy a niche in the market and has allowed it to flourish when others have had to reject such business. Clearly, this flexibility has become just one more way in which the company has fulfilled what M.B. Rich numbered sixth among the reasons the company succeeded: Satisfied customers.

Woolrich has been successfully producing outdoor clothing since the mill’s founding in 1830. The company has allowed people to comfortably engage in outdoor activities from backyard hunting to exploring the Antarctic. As Marketing Vice President Brent Hollowell said, “The Woolrich brand is an iconic American institution with a heritage that spans over 180 years.” He went on to laud the brand’s “authentic roots” and its continued relevance to the public. There is no doubt that with the hard work and commitment that goes into the company, Woolrich’s reputation will continue to grow.

The Center would like to thank Michael Collin of Pale Morning Media and Ronald C. Yeaton of Woolrich, Inc. for their assistance in the development and illustration of this article.

Sources:

- Becker, David. Personal Interview with Megan Baker. 1 Oct. 2010.

- Griggs, James E. Personal Interview with Alan Jalowitz. 6 May 2011.

- Pennsylvania Department of Conservation and Natural Resources. “Woolrich Marking 175th Year as an Outdoors Icon.” Resources. 10 May 2005. 17 Oct. 2010 <http://www.dcnr.state.pa.us/news/ resource/res2005/05-0510-woolrich.aspx>.

- Rich, M. B. History of the First 100 Years in Woolrich. Williamsport: Grit Press, 1930.

- “Rich, Robert Fleming.” Biographical Directory of the United States Congress. 2011. 15 May 2011 <http://bioguide.congress.gov/scripts/biodisplay.pl?index=R000209>.

- Tomb, Jeff. Personal Interview with Megan Baker. 1 Oct. 2010.

- Truax, Doug. Woolrich: 175 Years of Excellence. South Boardman, MI: Crofton Creek, 2005.

- Woolrich. Advertorial. “At Woolrich the Commitment to Conservation Runs Deep.” Backpacker, Mar. 2008: 138.

- Woolrich® The Original Outdoor Clothing Company. 2010. 28 Sept. 2010 <http://www.woolrich.com/>.

- “Woolrich Hires Brent Hollowell as Marketing VP.” Lock Haven Express. 7 May 2011. 28 June 2011. <http://www.lockhaven.com/page/content.detail/id/531481/Woolrich-hires-Br....

- “Woolrich Returns to Antarctica in Support of Polar Cap Exploration.” KansasCity.com. 13 Oct. 2010. Kansas City Star. 13 Oct. 2010 <http://www.kansascity.com/2010/10/13/2310222/woolrich-returns-to-antarct....

- Yeaton, Ronald C. Personal Interview with Alan Jalowitz. 6 May 2011.

GALLERY